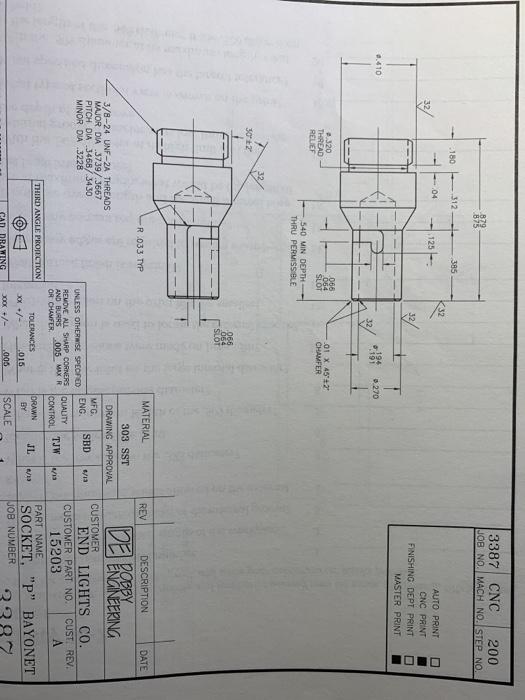

√70以上 3/8-24 unf-2a pitch diameter 185699-3/8-24 unf-2a pitch diameter

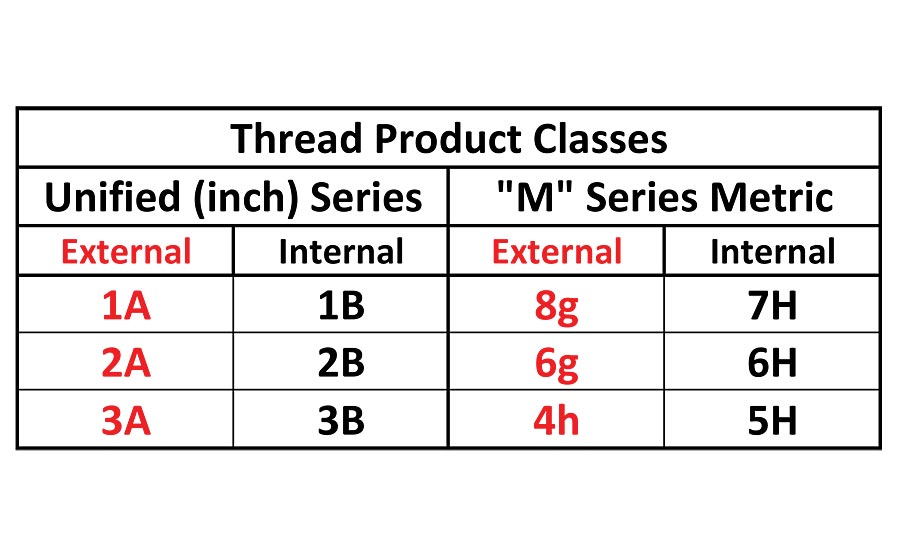

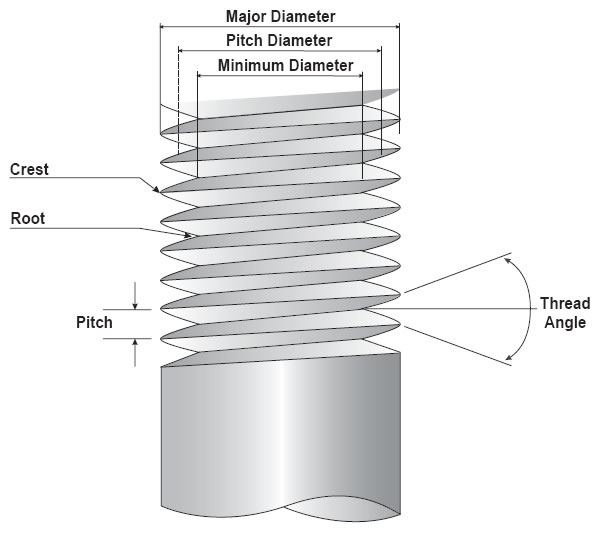

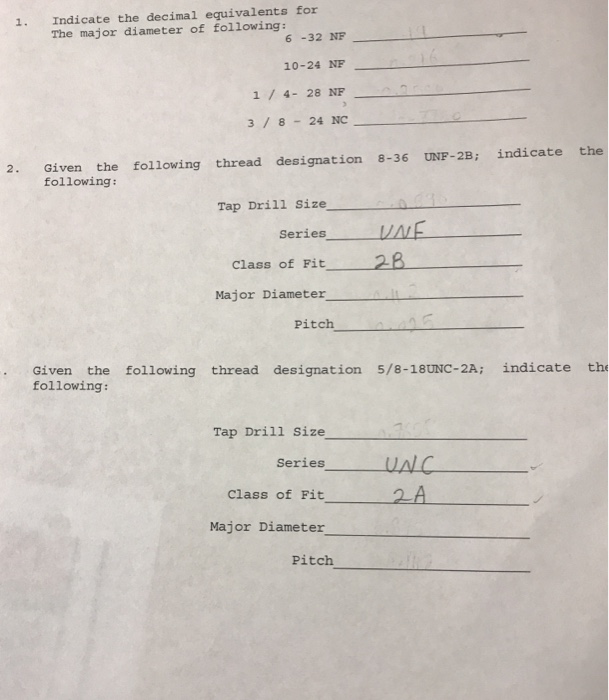

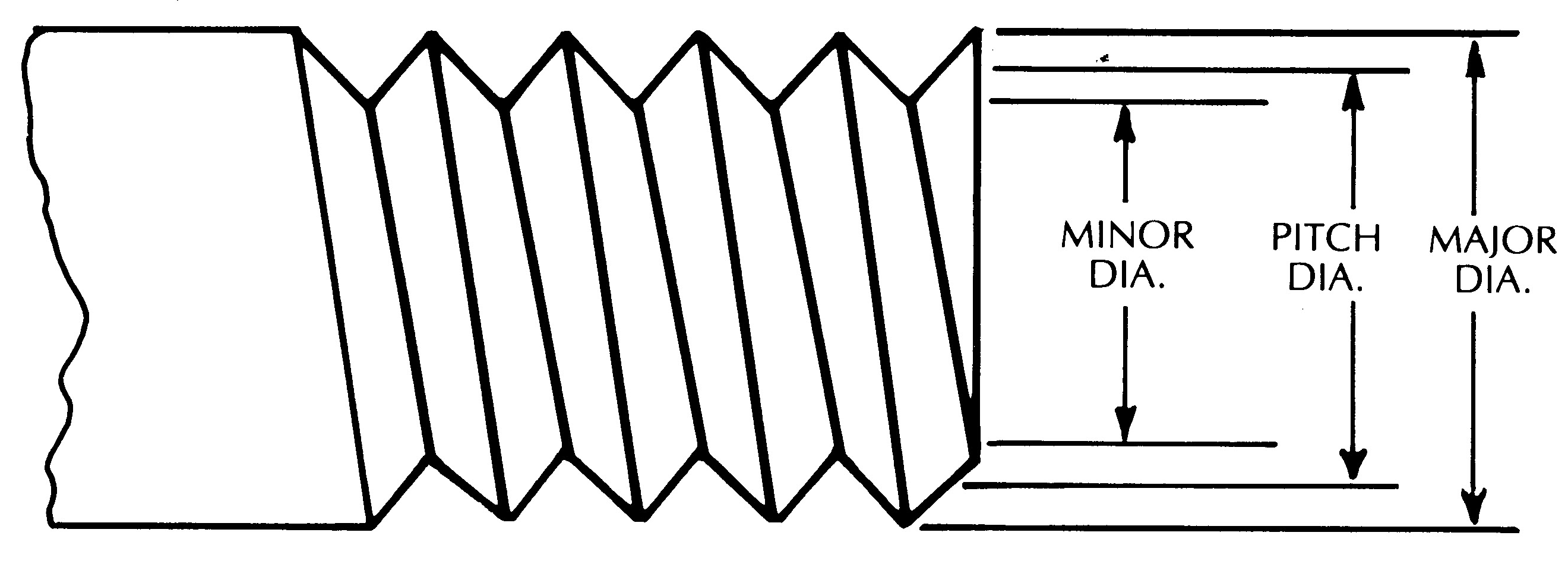

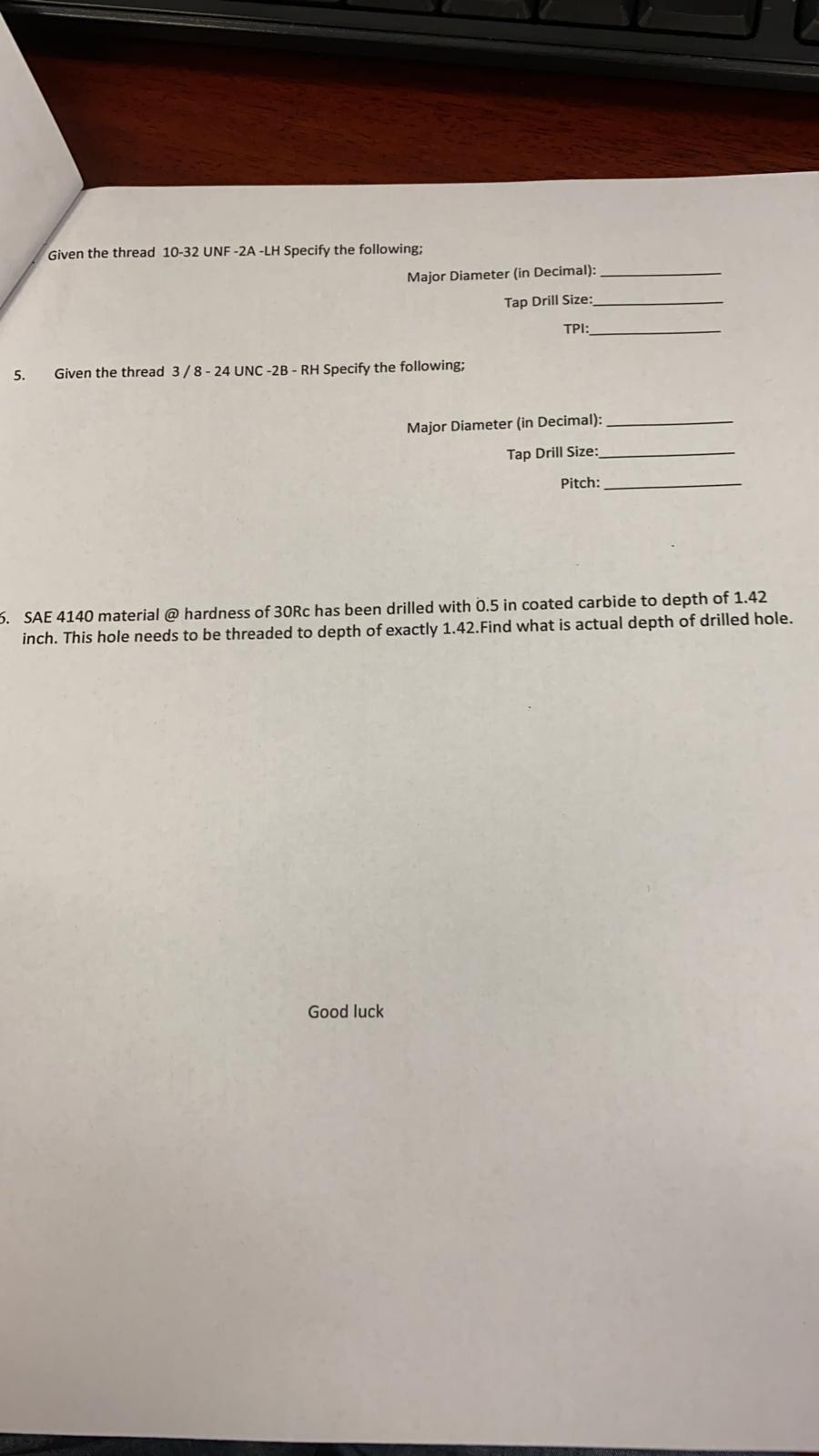

Diameter Pitch TPI Thread Fit Class Major Diameter Pitch Diameter Minor Diameter Stress Area Max Min Max Min Max Min in² No 1 64 2A No 2 56 2A No 3 48 2A 009 005EN Pipe threads where pressure tight joints are made on the threads Dimensions Pipe threads where pressure tight joints are made on the threads Part 1 Taper external threads and parallel internal threadsWire Diameters Diameter of the wires used to measure the dimension close to the pitch diameter the external screw thread Tolerances Allowance Fundamental deviation of the basic size, applies only to 1A and 2A external classes Major/Pitch/Minor diameters The difference between the maximum and minimum diameters

Ekstromcarlson Com Wp Content Uploads 16 09 Technical Threading Chart 15 Pdf

3/8-24 unf-2a pitch diameter

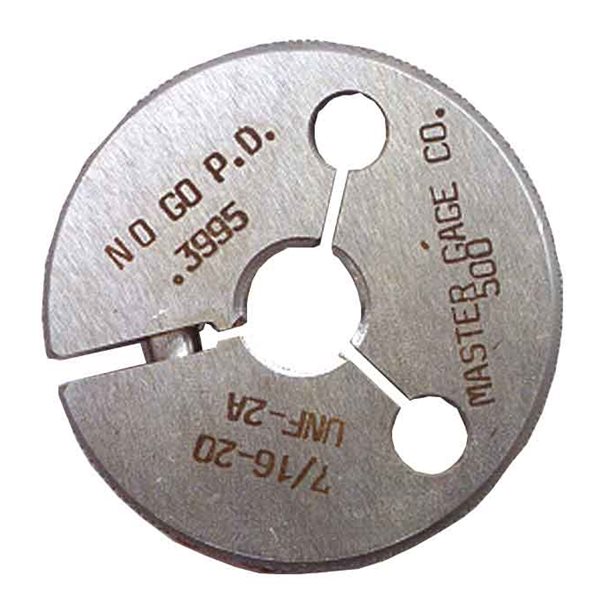

3/8-24 unf-2a pitch diameter-The external thread is a 3/4 UNF class 2A They assume that the internal thread must have the same 2A class of fit as the external thread they presently manufacture Based on this assumption, they contact their gage distributor / manufacturer and order a 3/4 UNF 2A plug gage The only 2A plug gage that exists is a setting plug3/4 UNF2A ~ Thread Ring Gage GO ONLY 375 24 ~ DoALL ~ LEFT HAND $3500 Free shipping I personally inspect every gauge, although I do not check Pitch Diameters of every gauge, if it appears they need it, I will measure the pitch diameter to verify it is correct

Q Tbn And9gctskbgnd3qtri4f I3hday1jbiqpfhtecmixuyo68lffe5qvjzx Usqp Cau

Nominal Diameter Major Diameter Inch Major Diameter mm Tapping Drill Size mm TPI Pitch mm #0 80 UNF 0060 1524 125 80 0317 #1 72 UNF 0073 1854 1The external thread is a 3/4 UNF class 2A They assume that the internal thread must have the same 2A class of fit as the external thread they presently manufacture Based on this assumption, they contact their gage distributor / manufacturer and order a 3/4 UNF 2A plug gage The only 2A plug gage that exists is a setting plugScrew thread gauges to one inch in diameter These series (and the UNR, UNJ and fixedpitch series) are the inchbased thread series currently used in the United States, and have been since They superceded the American National Series (NC, NF, etc) Pink shading indicates secondary sizes whose use is discouraged by standards organizations

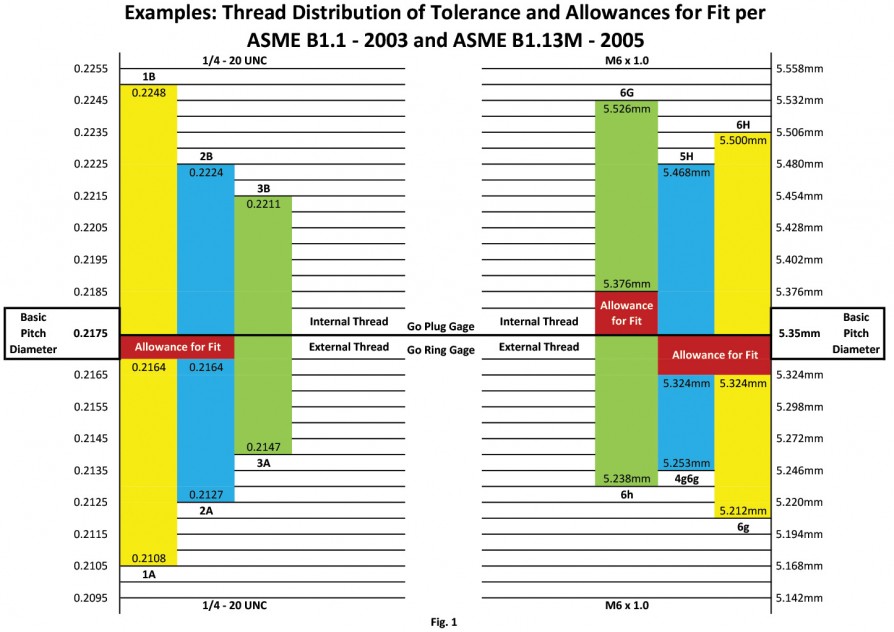

Nominal Size & Threads / Inch & Series Designation Allowance Minor Diameter Pitch Diameter Major Diameter Min Max Min Max Tolerance Min 080 164 172 256Unified Screw Thread Chart, UNC, UNF, UNEF, Major Diameter, Minor Diameter, Pitch, External Thread, Internal Thread, Size from #0 to 25The difference between class 2A and 3A external threads is shown for 5/818 UNF parts Note that for class 2A, both the major and pitch diameter maximums are below their respective basic values by the inch allowance The allowance is 30% of the class 2A tolerance For class 3A, the major and pitch diameter maximums are at the basic size

1/4 28 074 5/16Thread Major Diameter Thread Per Inch Pitch Diameter Minor Diameter Male Thread Minor Diameter Female Thread;8600 3/8 24 unjf mj10x15 rp 1/8 28 tr 10x15 8700 3/8 32 unef 1/8 27 npsf 11/32 8733 1/8 27 npsc 43 tap drill diameters for thread cutting nominal size ø d1 unc unf unef unjc unjf m mf mj npsm npsc npsf rp_ (bspp) g stiunc stiunf stim lkunc lkm bsw bsf pg tr trf rd

Hammondcompany Com Wp Content Uploads 17 09 Gage Assembly Catalog Pdf

Vermont Gage 3 8 24 Unf 2a No Go Ring Gage Absolutebeauty Co Za

Nominal size unified pitch diameter class 2a class 3a x tol go = – no go = go not go go not go #080 unf #164 uncNotes a) For Class 2A threads with coating (plating) the max is increased by the allowance, to the basic size This is the same valueHere are the standard thread sizes and constraining geometries recommended by Xometry Internal Threads Thread Hole Diameter(in) Max Thread Depth(in) UNC/UNF 080 UNC 0047 0157 1

Unified National Thread Unc And Unf

3 8 24 Unf 2a Thread Ring Gage Machinist Inspection Tooling Lathe Ebay

The Nominal Major Diameter and Threadsperinch (Pitch) are defined by ANSI/ASME B11 and are the choices for the customary Unified screws and nuts Nominal Diameter Major Diameter Inch Major Diameter mm Tapping Drill Size mm TPI Pitch mm #12 32 UNEF 5486 480 32 0794 1/4" 32 UNEF 6350 570 32 0794Standard inch pitch diameters basic, 2b, 3b, 2a, & 3a #0 060 80 unf 0519 0542 0536 0519 0506 0514 0496 9/16 5625 24 unef 5354 5405 5392 5354 5325 5342Thread Series, UN and UNR Series constant pitch threads with a pitch of threads per inch Numerical tabulation of sizes, major,minor, and pitch diameters Also the Minor Diameter and Tensile Stress areas

Everything You Wanted To Know About Taps But Were Afraid To Ask Styles Of Taps Class Of Thread Gh Numbers Basic Point In Thread Measurement Constants For Finding Pitch

Thread Classes And Setting Plug Gages 19 10 01 Quality Magazine

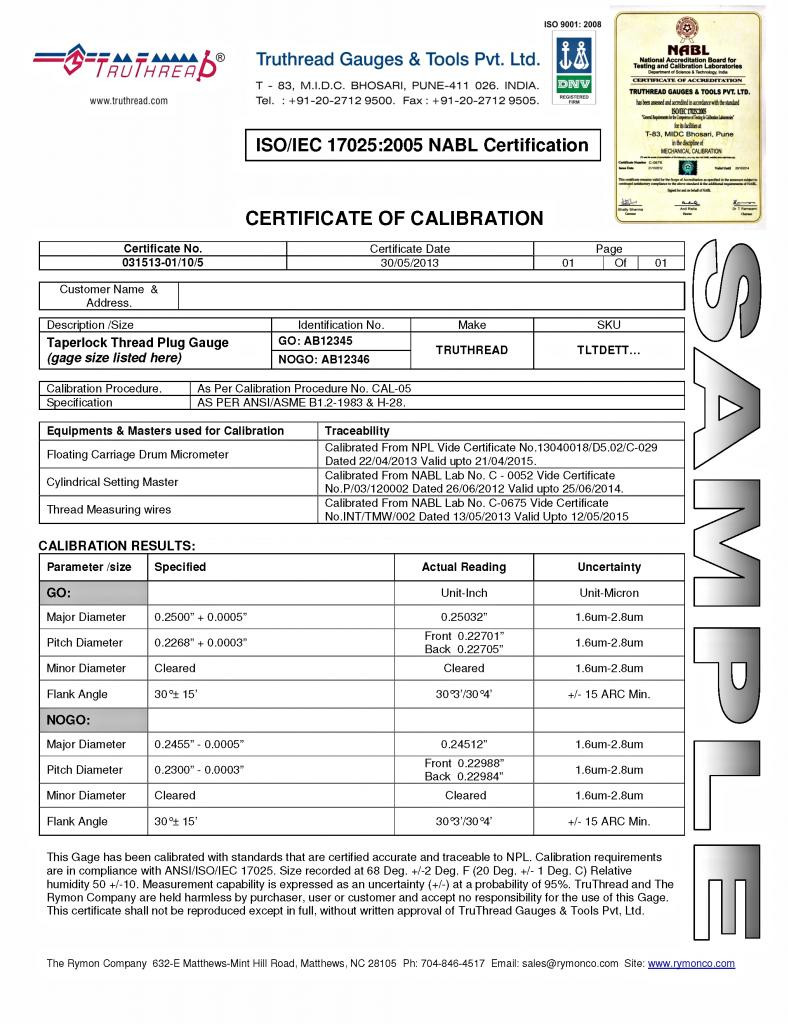

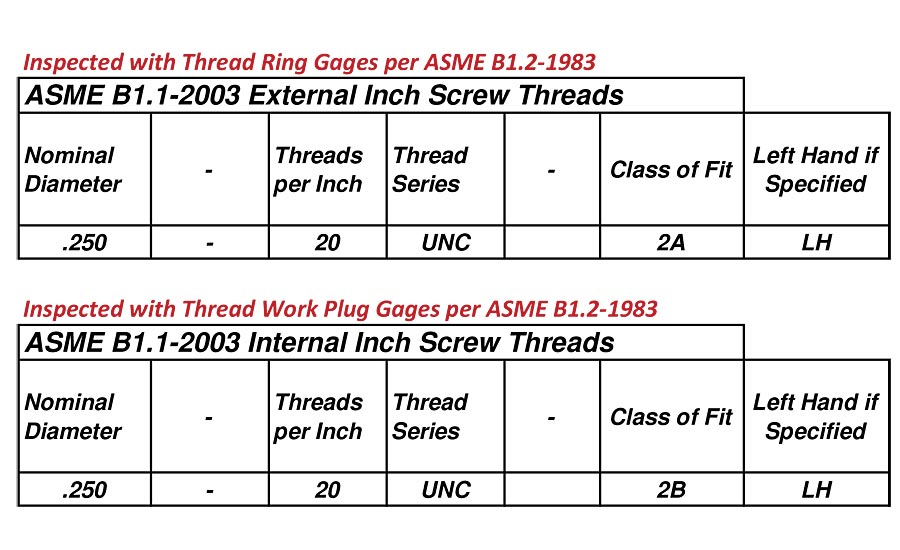

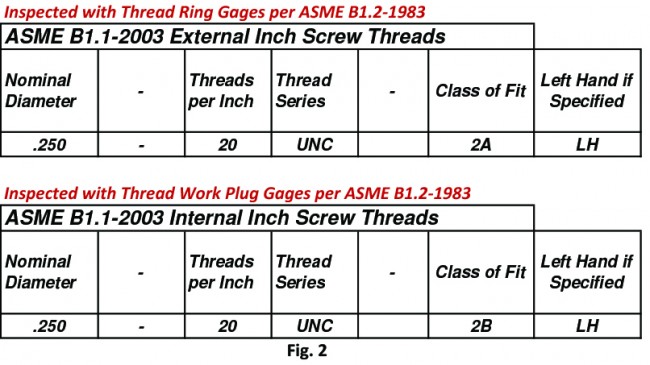

Check a part's external threads to ensure they fall within tolerance The part is within tolerance if it's easy to thread a go gauge onto the part but difficult to thread a nogo gauge more than two turns Go gauges check the maximum external thread size Nogo gauges check the minimum external thread size Threads have different classes of fit Thread fit designates the tightness orThread Major Diameter Thread per Inch Pitch Diameter Minor Diameter Male Thread Minor Diameter Female Thread;Screw thread gauges to one inch in diameter These series (and the UNR, UNJ and fixedpitch series) are the inchbased thread series currently used in the United States, and have been since They superceded the American National Series (NC, NF, etc) Pink shading indicates secondary sizes whose use is discouraged by standards organizations

3 8 24 Unf Class 2a Solid Design Thread Ring Go Gage The Rymon Company

Q Tbn And9gcrhfe57nsaspchjkoz1rutaet0eiyax3 Fqfzhq Qrokmgba Kq Usqp Cau

3/4 UNF Class 2A SolidDesign Thread Ring GO Gage Amazoncom Industrial & Scientific SolidDesign Thread Ring Gage for inspecting the pitch diameter and functional thread for external threaded products All gage members are serialized and include a printed Long Form Certificate from a Accredited companyThread Major Diameter Thread per Inch Pitch Diameter Minor Diameter Male Thread Minor Diameter Female Thread;1/4 28 074 5/16

Everything You Wanted To Know About Taps But Were Afraid To Ask Styles Of Taps Class Of Thread Gh Numbers Basic Point In Thread Measurement Constants For Finding Pitch

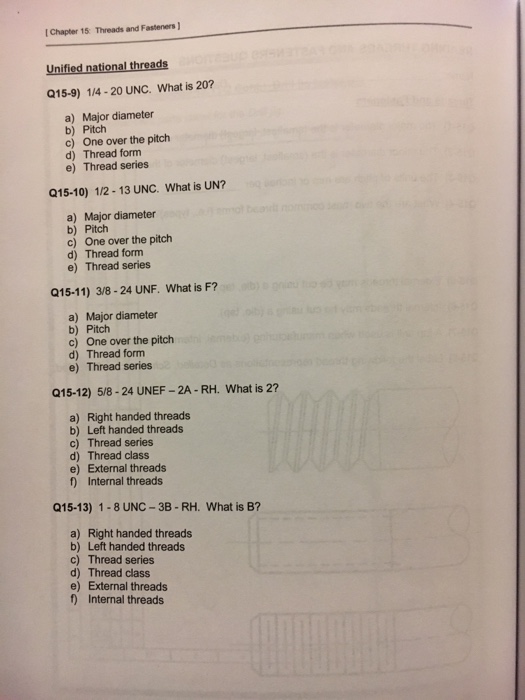

Solved Chapter 15 Threads And Fasteners Unified Nationa Chegg Com

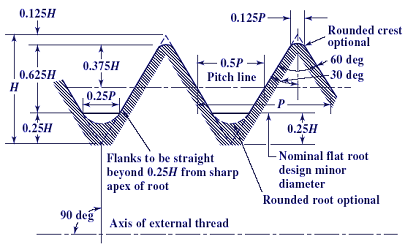

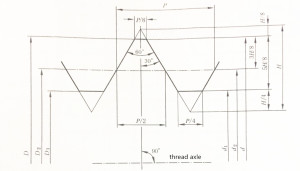

Pitch Diameter Size The Functional diameter size is the Pitch diameter size plus the cumulative effect of variations in lead, (including uniformity of helix) flank angle, taper, and roundness The Functional size is the measured value of the maximum material size of either a product internal or external screw thread The Pitch diameter sizeDiameter for pitchline contact = × Pitch If you do the math, you will find that all the suggested wires in the table above are between the smallest and largest values ©11 LittleMachineShopcom Page 4 of 4 The thread pitch for an American National Standard Unified 60 ° thread isWire Diameters Diameter of the wires used to measure the dimension close to the pitch diameter the external screw thread Tolerances Allowance Fundamental deviation of the basic size, applies only to 1A and 2A external classes Major/Pitch/Minor diameters The difference between the maximum and minimum diameters

Threads

Misc 3 8 24 Unf 3a Nogo Thread Ring Gage Gauge Pd 3450 Ebay

3 NTS I nternal t hreads C lass 2B ASME B1108 Nominal Size & Threads per Inch Series DesignationOn a ½13 UNC2A screw the pitch diameter tolerance is 0,127 mm Allowance from the nominal pitch diameter for 2A and 1A is 0,127 x 0,3 = 0,038 ie 03 x 2A pitch diameter tolerance 1A is 0,127 x 1,5= 0,1905 1B is 0,127 x 1,950 = 0,248 2B is 0,127 x 1,300 = 0,165 3A is 0,127 x 0,75= 0,095 3B is 0,127 x 0,975 = 0,124The 1/4"28 UNJF is a Unified fine pitch UNJ inch thread for aerospace There are other Unified UNJ threads such as UNJC coarse pitch threads and UNJEF ultra fine pitch threads The thread accuracy is referred to as a 3B class of fit or a 2B class of fit A 3B class of fit is considered a precision internal thread with a tighter accuracy

Screw Sizes Screw Sizing Chart Socket Cap Screw Data Asm

Www Sigmafasteners Com Catalog Section 5 Pdf

A For Class 2A threads with coating (plating) the max is increased by the allowance, to the basic size This is the same value as Class 3A b For uncoated hotrolled, but not standard fasteners with cold rolled threadsDiameter Threads Per Inch (TPI) Thread Fit Class Major Diameter Pitch Diameter Minor Diameter Stress Area Min Max Min Max Min in² No 0 80 2B No 1 72 2B No 2 64 2BDiameter Threads Per Inch (TPI) Major diameter (In) Major diameter (mm) Pitch Diameter (mm) Tap Drill Size(mm) N° 0 80 0060 1524 0317 125 N° 1 72

Efco Class 2a Thread Ring Gauge 7 8 14 Unf Ebay

Thread Ring Gauge Gage Assembly

The Nominal Major Diameter and Threadsperinch (Pitch) are defined by ANSI/ASME B11 and are the choices for the customary Unified screws and nuts Nominal Diameter Major Diameter Inch Major Diameter mm Tapping Drill Size mm TPI Pitch mm #0 80 UNF 3/8" 24 UNF 9525 850 24 1058 7/16" UNFThe difference between class 2A and 3A external threads is shown for 5/818 UNF parts Note that for class 2A, both the major and pitch diameter maximums are below their respective basic values by the inch allowance The allowance is 30% of the class 2A tolerance For class 3A, the major and pitch diameter maximums are at the basic sizeTap size NF/NC UNF/UNC Threads per inch Basic major dia (inches) Basic effective dia (inches) Basic minor dia of ext threads (inches) Basic minor dia of int threads (inches)

Www Threadcheck Com Images Pdf Tcicatalog 12 Pdf

Un Imperial Screw Thread Calculator

Standard Pitch Diameter Chart 17 PRECISION GAGES FOR QUALITY ASSURANCE Ring Thread Gages and Setting Plugs NOMINAL SIZE X TOL GO = – NO GO = UNIFIED PITCH DIAMETER GO NOT GO GO NOT GO CLASS 2A CLASS 3A 9/ 16 24 UNEF 5342 5303 5354 5325 0003 5/ 8 11 UNC 5644 55 5660 5619 0003 5/ 8 18 UNF 5875 58 58 5854 0003 5/Nominal Thread Size Covered Range 080 UNF to ¼56 UNS Nominal thread sizes from 080 UNF to ¼56 UNS 5/1618 UNC to 9/16 32 UN Nominal thread sizes from 5/1618 UNC to 9/16 32 UNTHREAD PITCH CHART (UNC / UNF / UNEF / UN) Thread pitch chart for UNC, UNF, UNEF and UN up to 2 inch according to ASME B11

Unified National J Series Vs Unified National

Www Redlinetools Com Customer Docs Skudocs Tap General Purpose Speeds P405 416 Pdf

Nominal Diameter Major Diameter Inch Major Diameter mm Tapping Drill Size mm TPI Pitch mm #0 80 UNF 0060 1524 125 80 0317 #1 72 UNF 0073 1854 18600 3/8 24 unjf mj10x15 rp 1/8 28 tr 10x15 8700 3/8 32 unef 1/8 27 npsf 11/32 8733 1/8 27 npsc 43 tap drill diameters for thread cutting nominal size ø d1 unc unf unef unjc unjf m mf mj npsm npsc npsf rp_ (bspp) g stiunc stiunf stim lkunc lkm bsw bsf pg tr trf rdDD is the major diameter of the thread Thus 3/8inch thread will have a 3/8 standing at the left most of the thread specification The dimensions usually come at margins of an inch (1/2, ¼, 1/8 ,1/16 etc) It must be noted that threads with a diameter smaller than ¼ have been given special numbers, from 0 to 10

Thread Data Charts Unef Screw Threads Per Ansi B1 1

Q Tbn And9gctskbgnd3qtri4f I3hday1jbiqpfhtecmixuyo68lffe5qvjzx Usqp Cau

Pitch Diameter (in) Minor Diameter External (in) a) Minor Diameter Internal (in) b) Minor Diameter Area (sq in) Tensile Stress Area (sq in) * Secondary Size a) Form for UNR thread b) Basic Minor Diameter;THREADSALL / ZGFI style 2xD single plane thread mill for difficult materials UNC/UNF & UNJ/UNJF thread forms Certain diameters can cut M and MJ threads Each thread mill can cut multiple thread pitch combinations Check with brochure table for exact sizes 1 to 6 teeth profile Coolant fed options over 5/16" Tools provide control of pitch diameter including 2B, 3B, 3BG and all1 7/16 18 1 1/2

Unified National Threads

Mae Ufl Edu Designlab Online resources Files Fastener Handout Pdf

3/4 UNF Class 2A SolidDesign Thread Ring GO Gage Amazoncom Industrial & Scientific SolidDesign Thread Ring Gage for inspecting the pitch diameter and functional thread for external threaded products All gage members are serialized and include a printed Long Form Certificate from a Accredited company3/4 unf 24 3750 3479 3239 3299 q 7/1614 unc 14 4375 3911 3499 3602 u 7/16 unf 4375 4050 3762 34 25/64 1/213 unc 13 5000 4500 4056 4167 27/64 1/2 unf 5000 4675 4387 4459 29/64 9/1612 unc 12 5625 5084 4603 4723 31/64 9/1618 unf 18 5625 5264 4943 5024 33/64 5/811 unc 11 6250 5660 5135 5266 17/32On a ½13 UNC2A screw the pitch diameter tolerance is 0,127 mm Allowance from the nominal pitch diameter for 2A and 1A is 0,127 x 0,3 = 0,038 ie 03 x 2A pitch diameter tolerance 1A is 0,127 x 1,5= 0,1905 1B is 0,127 x 1,950 = 0,248 2B is 0,127 x 1,300 = 0,165 3A is 0,127 x 0,75= 0,095 3B is 0,127 x 0,975 = 0,124

Www Swansongage Com Customer Content Www Cms Files Precision Thread Plain Gage Pdf

Screw Thread Wikipedia

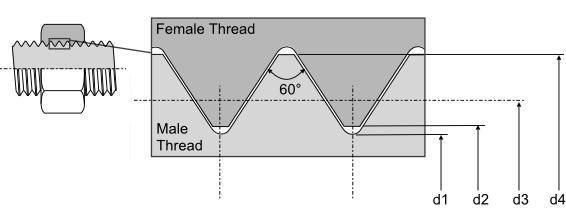

UNF plug gages GGRLD are designed to inspect the pitch diameter and functional thread for internalthread components All plug gages are available with Certificate of Accuracy documentation Gage dimensions according to ANSI/ASME B12 Short form certificate is supplied at no additional charge Long form certificate is available on request Thread gages are for UNF 2B classEach thread in the series is characterized by its major diameter D maj and its pitch, PUTS threads consist of a symmetric Vshaped thread In the plane of the thread axis, the flanks of the V have an angle of 60° to each other The outermost 1 ⁄ 8 and the innermost 1 ⁄ 4 of the height H of the Vshape are cut off from the profile The pitch P is the distance between thread peaksCast Iron Flanges Stud Reference Chart The number, diameter and length of studs for cast iron flanges class 125 and 250;

Http Www Actequipment Com Gage Pdfs Pitchun Pdf

Http Svmicro Com Sites Default Files Documents Supplier Reference Guide 0715 Pdf

Your pitch diameter tolerance is " and a max plating of will reduce your pitch diameter by max (4 flanks) Chances are more than reasonable that a standard 3/8 24 UNJF tap would be within the tolerance IF YOU DARE TAKE THE CHANCE 1214, 0235 PM #3 gsxr100

Thread Ring Gauge 3 8 24 Unf 2a Go Mikromierz Pl

Unf Thread Ansi Asme B1 1

Ekstromcarlson Com Wp Content Uploads 16 09 Technical Threading Chart 15 Pdf

Everything You Wanted To Know About Taps But Were Afraid To Ask Styles Of Taps Class Of Thread Gh Numbers Basic Point In Thread Measurement Constants For Finding Pitch

Teco Tapped Hole Location Gauges Dimension D 1 Dimension E 3 8 Thread A 3 8 24 Unf Dia B 1 2 Dia C 2500

Vermont Gage 0 80 Unf 2a No Go Ring Gage Amazon Com Industrial Scientific

Hemco Go Thread Ring Gage 3 8 24 Unf 2a Surplus Select

Thread Gauges

Vermont Gage 0 80 Unf 2a Go Ring Gage Amazon Com Industrial Scientific

3 8 24 Unf 3a Left Hand Thread Ring Gages 375 Go No Go Pds 3479 3450 L H Ebay

Hammondcompany Com Wp Content Uploads 17 09 Gage Assembly Catalog Pdf

Www Swansongage Com Customer Content Www Cms Files Precision Thread Plain Gage Pdf

Solved 1 Indicate The Decimal Equivalents For The Major Chegg Com

D2t1xqejof9utc Cloudfront Net Files Thread data chart Pdf

Www Sigmafasteners Com Catalog Section 5 Pdf

3 8 24 Go No Go Screw Plug Gauges Unf Description 3 8 X 24 Unf Go No Go Screw Plug Gauge Double Ended Class 2b Gauges For Testing Unified Threads To Bs

Vermont Gage 106 06 Adj No Go Ring Gage 3 8 24 Unf 2a Zoro Com

Thread Ring Gage 3 8 24 Unf 2a Lo P D 3430 Royal Ebay

Unc Bolt Sizes Unf Bolt Sizes Threading Machine Resources

Solved Given The Thread 10 32 Unf 2a Lh Specify The Follo Chegg Com

Quotation Un Rings Ring Plug Thread Gages

3 8 24 Unf 2a Thread Ring Gage Go Not Go 375 24 Dura Ebay

Solved 1 5 Activity 18 8 P Bayonet Socket Refer To A Chegg Com

Cdn Thomasnet Com Ccp Pdf

Product And Technical Support Resources Vermont Gage

Thread Pitch Chart

3 8 24 Unf Thread Gauge 3 8 24 Unf Ring Plug Gage 2a 2b Go Nogo Gaugestools

Unified Fine Unf

Www Fastenal Com Content Feds Pdf Article screw threads design Pdf

Hemco 3 56 Unf 2a Thread Go Ring Gauge Business Industrial Metalworking Inspection Measurement

Www Swansongage Com Customer Content Www Cms Files Precision Thread Plain Gage Pdf

3 8 24 Unf 3a 0 375 Thread Ring Gauge Nogo Not Go 0 3450pd Dura Gage Sold As Is Ebay

Www Teesing Com Files En Brochures Type Of Thread Pdf

Unified National J Series Vs Unified National

Www Yamawa Com Portals 0 Resource En Tips Pdf Tips 063 Pdf

9dsu6zdp0osdvm

Vermont Gage Go Nogo Standard Thread Gauge Set Class X Asme B1 2 2a Ring 3 8 24 Unf Thread Size 3t Handle Thread Gauges Amazon Com Industrial Scientific

3 8 24 Unf 2a Thread Ring Gage Go Only 375 24 Doall Left Hand Ebay

Www Threadcheck Com Content Pdf Thread Check Catalog 16 Pdf

3 8 16 Unc 2a Thread Ring Gage Go Not Go 375 16 Tpi Hemco Dura 45 00 Picclick

3 8 24 Unf 2a Special Pitch Dia Thread Ring Gage 375 Go Only P D 3460 Nf 2a Ebay

Screw Sizes Screw Sizing Chart Socket Cap Screw Data Asm

Thread Classes And Setting Plug Gages 19 10 01 Quality Magazine

Http Www Steelmasters Co Nz Webfiles Steelmastersnz Files External Internal Thread Dimensions For Unf Screw Thread 16 Pdf

Unified Inch Thread Ring Gages Thread Ring Gauges

Www Fastenal Com Content Feds Pdf Article screw threads design Pdf

Automotive Heavy Duty Muffler Clamps U Bolts Stainless Steel Band Clamps Ohio Clamps Inc

Kbc Usa 3 8 24 Unf 2a No Go Ring Gage 1 813r 34n Kbc Tools Machinery

Imperial Fasteners Fabory

Everything You Wanted To Know About Taps But Were Afraid To Ask Styles Of Taps Class Of Thread Gh Numbers Basic Point In Thread Measurement Constants For Finding Pitch

Q Tbn And9gctskbgnd3qtri4f I3hday1jbiqpfhtecmixuyo68lffe5qvjzx Usqp Cau

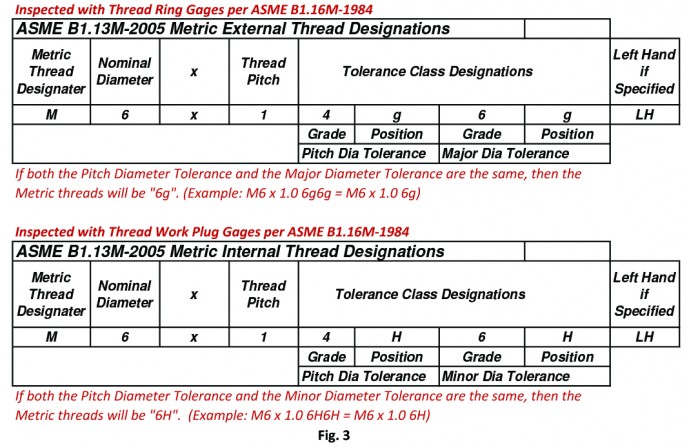

Understanding Thread Names How To Read Thread Designations For National Unified Threads Unc Unf Unef Un Bright Hub Engineering

3 8 24 Unf 2a Special Pitch Dia Thread Ring Gage 375 Go Only P D 3460 Nf 2a Ebay

Thread Classes And Setting Plug Gages 19 10 01 Quality Magazine

Product And Technical Support Resources Vermont Gage

Pdf4pro Com Cdn Iso Inch Thread With A Standard Unf 3b Tolerance 535fce Pdf

Mae Ufl Edu Designlab Online resources Files Fastener Handout Pdf

Amazon Com Allied Titanium Pack Of 3 3 8 24 X 1 1 4 Unf Titanium Hex Head Bolt Grade 5 Ti 6al 4v Industrial Scientific

Vermont Gage 106 06 Adj No Go Ring Gage 3 8 24 Unf 2a Zoro Com

Thredco 3 8 24 Unf 2a Nogo Thread Ring Gage Gauge Pd 3430 00 Picclick

Www Sigmafasteners Com Catalog Section 5 Pdf

3 8 24 Unf Class 2a Solid Design Thread Ring Go Gage Amazon Com Industrial Scientific

Unified Series Keensert 3 8 24 Class 3b Non Internal Thread Locking Kn624j Ms510 4 From Specialty Fasteners Components

Regal Go Thread Ring Gage 3 8 24 Unf 2a And 50 Similar Items

D2t1xqejof9utc Cloudfront Net Files Thread data chart Pdf

3 8 24 Unf Thread Gauge 3 8 24 Unf Ring Plug Gage 2a 2b Go Nogo Gaugestools

Vermont Gage Go No Go Set Plug Assy 3 8 24 Unf 2a Walmart Com Walmart Com

Un Thread Gauges Un Ring Gage Un Plug Gage Go Nogo Gaugestools

Www Teesing Com Files En Brochures Teesing Type Of Thread Pdf

Q Tbn And9gcsht1uvlthwcxyfomxdepatbilk1dp1wq 9mmmmp8aukgqhudqo Usqp Cau

Product And Technical Support Resources Vermont Gage

The Basics Of External Threads Threads Part 1 Wilson Garner Company

Un Imperial Screw Thread Calculator

Mxbaoheng 3 8 24 Unf Thread Ring Gage 2a Go Nogo High Precision External Screw Gauge Amazon Com Industrial Scientific

The Gage Store Measurement Tools And Accessories

Table Thread Reference Joining Cutting Tools

コメント

コメントを投稿